Precision Chemistry Demands of Semiconductor Processes

Precision, Purity, and Process Control at Every Step

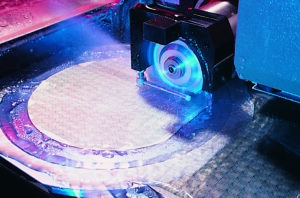

As nodes shrink and device complexity grows, manufacturers face strict design criteria for achieving the desired device performance which drives the need for flatter, smoother, ultra-clean surfaces.

The planarization of layers in advanced devices and materials increases demand for creative surface preparation consumables—including slurries, oxidizers, pads, and post-CMP rinses and cleaning chemistries.

In later-stage processing, the value of each wafer rises exponentially—making precise, defect-free dicing and cleaning critical for yield protection and device reliability.

IDI delivers a portfolio of high-performance chemistries designed for key semiconductor manufacturing workflows—from substrate shaping to final cleaning

Intersurface Dynamics focuses on the complex problems inherent in producing today’s most sophisticated ICs, with expertise in the process areas of surface finsihing, planarization and packaging. This expertise has resulted in highly developed chemistry for chemical mechanical polishing and post-CMP cleaning; grinding and lapping, dicing/singulation and post-dice cleaning/passivation rinse.

Though most semiconductor devices are fabricated on silicon wafers, compound semiconductor materials such as SiC, GaAs, GaN and InP, are now also being used for their advantages in applications that demand high power or high switching frequency. Regardless of the material, semiconductor substrates must be ultra-flat and defect-free.

IDI offers polishing compounds and cleaning chemistries for a wide range of semiconductor related materials:

- Application specific additives and fully formulated CMP slurries

- Compatible with hard-to-process materials like SiC and GaN

- Support planarization, thinning, and advanced packaging processes

- Application specific detergents and fully formulated PMCP cleans

- Remove slurry, silicon dust, and process residue

- Prevent corrosion and surface contamination

- Support wet storage, pad rinsing, and wafer de-chucking

Expert Solutions, Engineered for You

Specialized Solutions for Advanced Semiconductor Fabrication

Amtech Semiconductor Fabrication Solutions is a division of Amtech Systems, Inc., a global provider of equipment and materials for the semiconductor industry. This segment supplies capital equipment and consumables used throughout the semiconductor fabrication process—including advanced packaging and electronics manufacturing—covering everything from substrate processing to final assembly.

The Intersurface Dynamics, Entrepix, and PR Hoffman brands of Amtech Semiconductor Fabrication Solutions stand out for their commitment to custom solutions — whatever the customer needs, they deliver. Beyond customization, their competitive edge lies in responsiveness emphasizing quick turnaround times to meet customer demands. Additionally, each brand operates with a deep, process-specific focus, bringing together specialists within closely related fields. This structure ensures that customers benefit from true expertise tailored to their specific manufacturing challenges.

At Amtech Semiconductor Fabrication Solutions, we empower your manufacturing process through expert collaboration. Our specialized subsidiaries—Intersurface Dynamics, PR Hoffman, and Entrepix—bring unparalleled expertise in application-specific chemicals, polishing and lapping templates, and CMP-related upgrades. As a nimble and responsive company, we excel in forming rapid partnerships, allowing us to customize solutions that address your unique challenges. Together, we enhance every critical step of your semiconductor, compound semiconductor, and substrate manufacturing processes, driving innovation and precision.

Semiconductor Substrate Manufacturing Process

Input Substrate

- Si (silicon)

- SiC (silicon carbide)

- GaN (gallium nitride)

- GaAs (gallium arsenide)

- InP (indium phosphide)

- Glass

- Sapphire

Output

Finished Wafer or Substrate

Get the Right Chemistry for Your Process

We specialize in application-specific solutions—tailored to your materials, process, and performance goals. Whether you need help selecting the right product or developing a custom formulation, our experts are here to help.

Featured Products

Get the Right Chemistry for Your Process

Tailored solutions start with a conversation. Whether you need help selecting a product or developing a custom formulation, our experts are here to help.